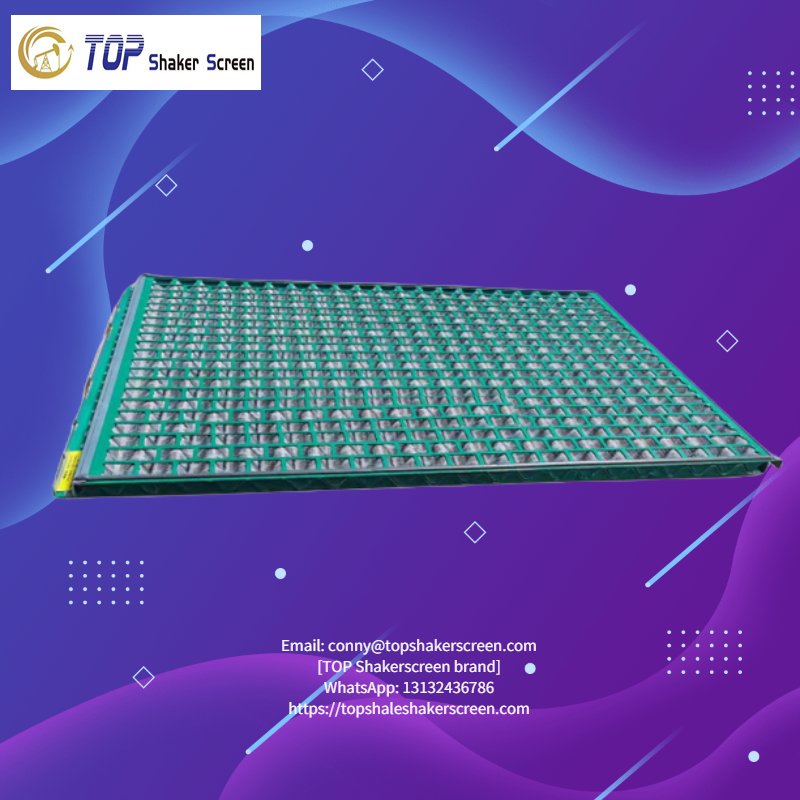

Mining Mud Separation Shaker Screen Scenario 2025 by TOP Shaker Screen

Discover the Mining Mud Separation Shaker Screen Scenario 2025 by TOP Shaker Screen. See performance in tough mining conditions.

Mining Mud Separation Shaker Screen Scenario 2025 by TOP Shaker Screen

Discover the Mining Mud Separation Shaker Screen Scenario 2025 by TOP Shaker Screen. See performance in tough mining conditions.

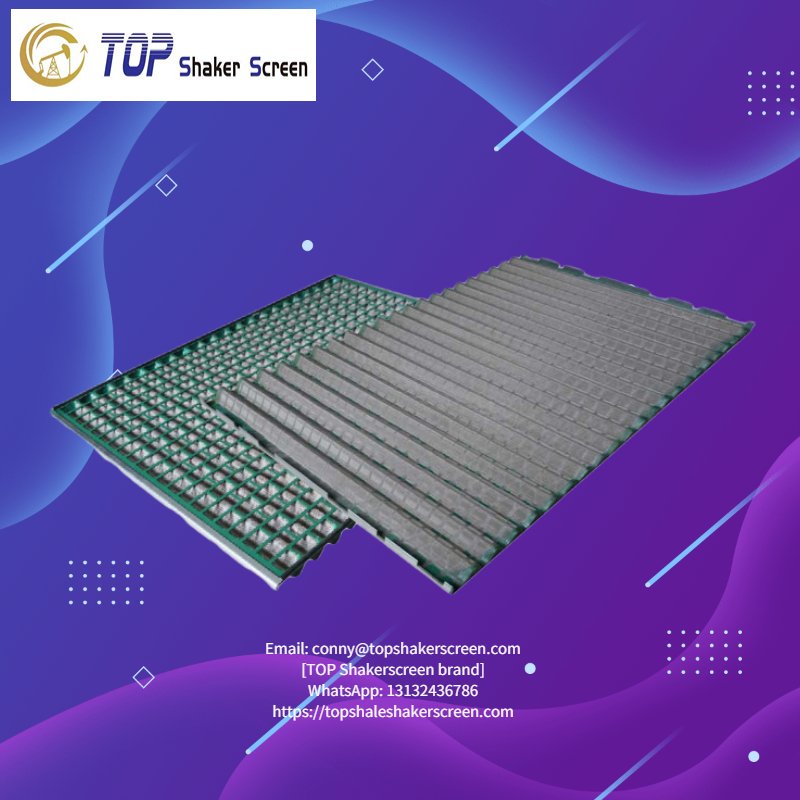

Oil Drilling Shaker Screen Application Scenario 2025 by TOP Shaker Screen

Oil Drilling Shaker Screen Application Scenario 2025 by TOP Shaker Screen

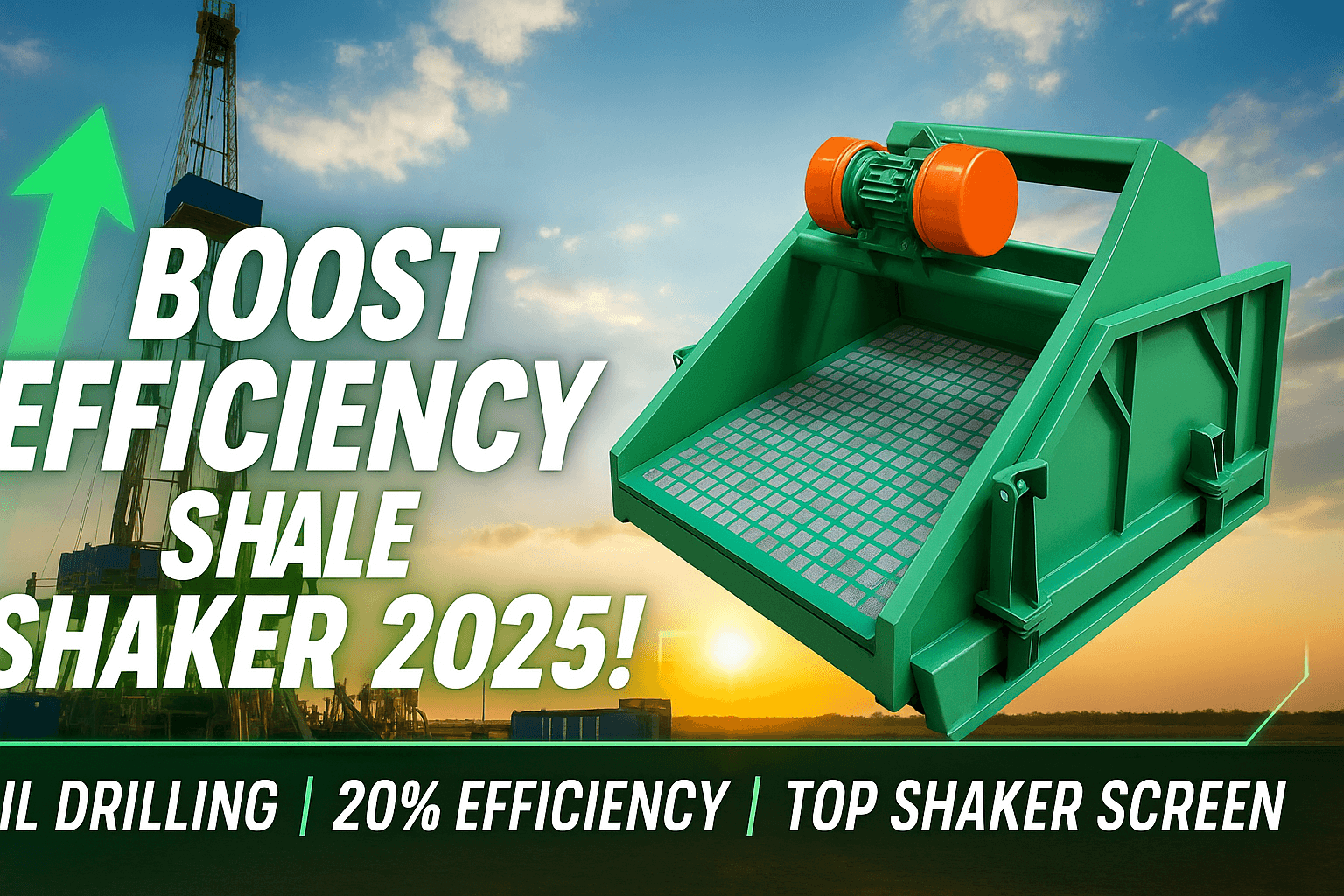

Shale Shaker Screen Efficiency Boost for Oil Drilling 2025

Learn Shale Shaker Screen Efficiency Boost for Oil Drilling 2025 by TOP Shaker Screen.

Discover how technology boosts operational efficiency in drilling projects.

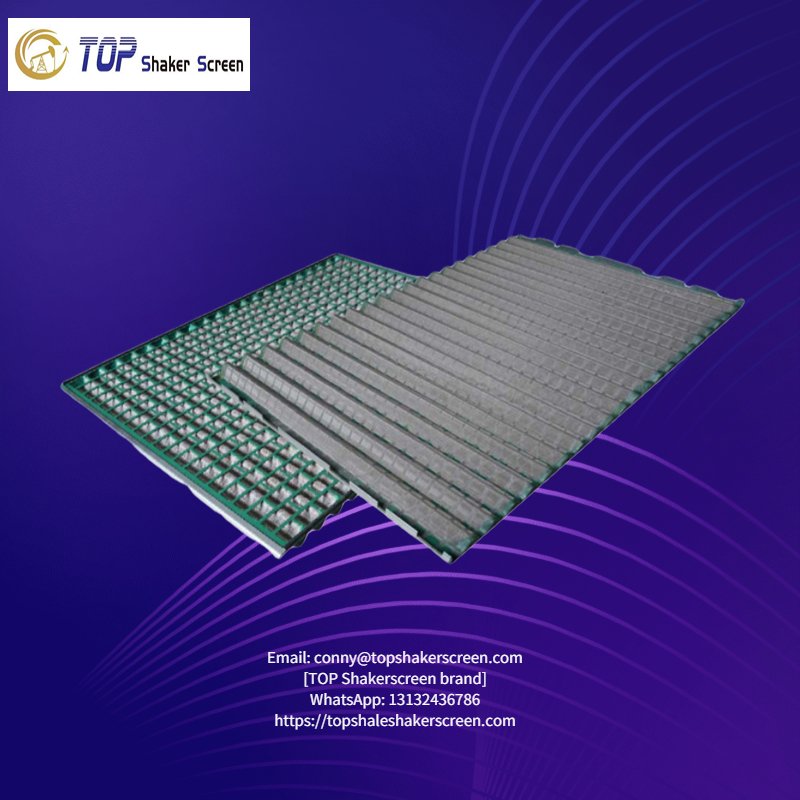

Shale Shaker Screen Innovation 2025 by TOP Shaker Screen

shale shaker screen, innovation 2025, oil drilling, TOP Shaker Screen, technology innovation` Discover Shale Shaker Screen Innovation 2025 by TOP Shaker Screen.

Explore the latest innovations in shale shaker screen technology for enhanced oil drilling efficiency.

Mining Mud Separation Shaker Screen Scenario 2025 by TOP Shaker Screen

Mining, Shaker Screen, Mud Separation, TOP Shaker Screen

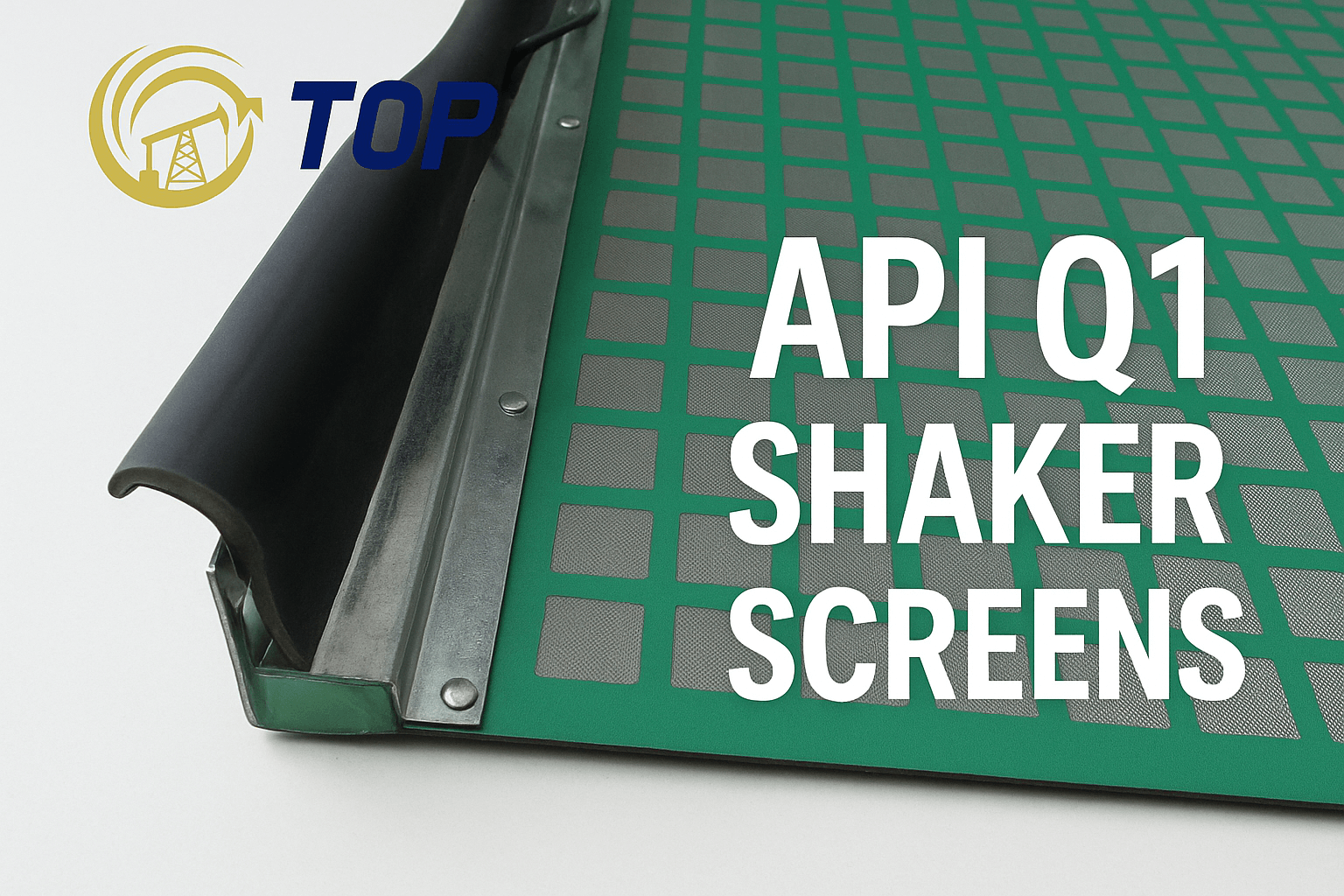

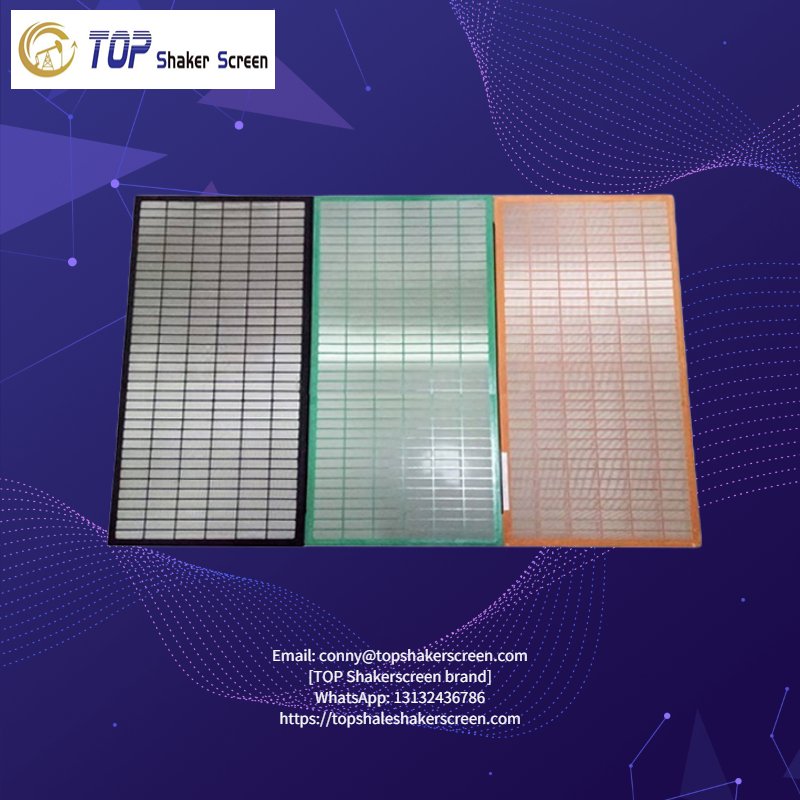

Advanced Shale Shaker Screen Technology Demo 2025 by TOP Shaker Screen

Explore the Advanced Shale Shaker Screen Technology Demo 2025 by TOP Shaker Screen. Discover innovative shale shaker screen technology with API-compliant solutions for oil drilling efficiency.

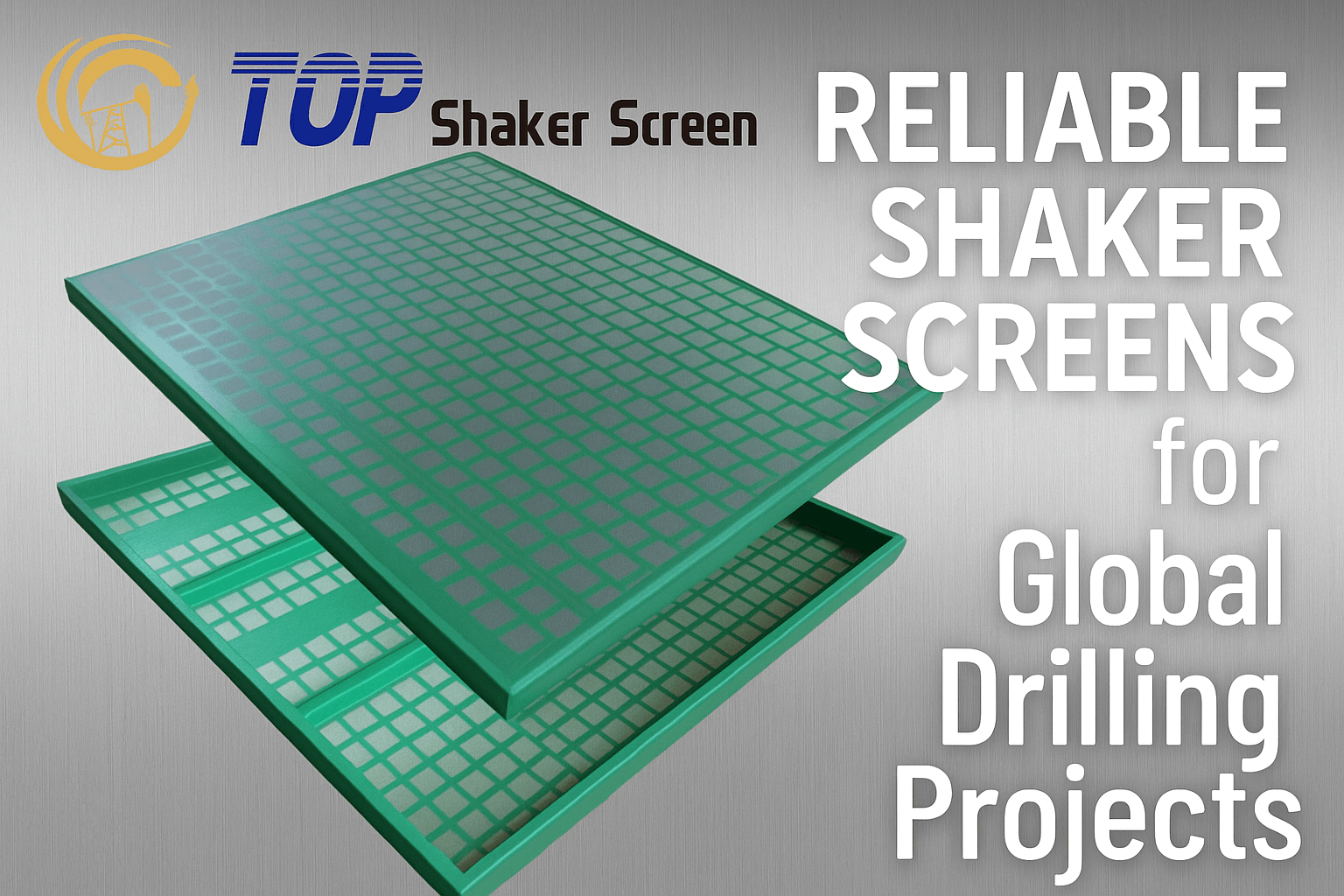

High Quality API Shaker Screens for Drilling Mud Solids Control | TOP Shaker Screen

TOP Shaker Screen provides high quality API shaker screens for efficient drilling mud solids control. Our screens meet API standards and deliver superior durability and performance in the oilfield.

Durable Composite Shaker Screens for Drilling Solids Control | TOP Shaker Screen

Explore TOP Shaker Screen’s durable composite shaker screens designed for superior solids control in oilfield drilling.

Our API certified composite screens offer enhanced strength and long-lasting performance.

High-Performance Shale Shaker Screens for Drilling Mud Solids Control | TOP Shaker Screen

Discover TOP Shaker Screen’s high-performance shale shaker screens designed for efficient mud solids control in oilfield drilling. Our API certified screens deliver durability and precise solids separation.

OEM Replacement Shaker Screens for Drilling | Reliable & Durable | TOP Shaker Screen

TOP Shaker Screen offers OEM replacement shaker screens designed for reliable solids control in drilling mud systems. Our durable screens are compatible with multiple shaker brands and manufactured to API standards.

Premium API Shaker Screens for Drilling Solids Control | TOP Shaker Screen

TOP Shaker Screen offers premium API shaker screens designed for efficient solids control in oilfield drilling.

Our products ensure durability, precise filtration, and compatibility with major shaker brands worldwide.

Durable Composite Shaker Screens for Drilling | API & OEM Standard | TOP Shaker Screen

TOP Shaker Screen provides durable composite shaker screens that meet API and OEM standards, designed for optimal performance and longevity in drilling mud solids control systems worldwide.

High Quality Drilling Shaker Screens | Durable API & OEM Replacement Screens | TOP Shaker Screen

TOP Shaker Screen offers high-quality drilling shaker screens with API and OEM certifications, designed for reliable solids control and long-lasting performance in oilfield drilling applications worldwide.

Oilfield Shale Shaker Screens for Solids Control | API & OEM Mesh Manufacturer | TOP Shaker Screen

TOP Shaker Screen offers OEM-quality shale shaker screens designed for oilfield solids control. Our screens comply with API RP 13C,

re compatible with most major shale shakers, and ensure efficient mud filtration and long service life.

Durable Composite Shaker Screens for Drilling | OEM API Screens Supplier | TOP Shaker Screen

High-performance composite shaker screens designed for durability and compatibility with major shale shakers.

TOP Shaker Screen delivers API certified products trusted by drilling contractors, mud system suppliers, and oilfield services worldwide.

Premium Shaker Screens for Oilfield Drilling | Composite & Steel Frame | TOP Shaker Screen

Explore TOP Shaker Screen’s premium shale shaker screens including composite and steel frame types.

Built to API standards and optimized for solids control in drilling, these screens deliver durability, performance, and compatibility. Ideal for HDD, oil & gas, geothermal, and mining.

TOP SHAKER SCREEN: Your Partner for Geothermal and Water Well Drilling

From renewable energy to clean water access, [Geothermal Drilling] and [Water Well Drilling] are shaping a sustainable future. TOP SHAKER SCREEN, a China-based leader in [Drilling Rig Shaker Screens], offers [Solids Control] solutions that meet [API Q1] standards. Whether you’re an environmental company like Environmental Solutions or a drilling contractor, our [Oilfield Supplies] ensure your projects succeed.

Why Choose TOP SHAKER SCREEN for Your Horizontal Directional Drilling (HDD) Projects

[Horizontal Directional Drilling] (HDD) is revolutionizing infrastructure projects worldwide, from pipelines to utilities. At TOP SHAKER SCREEN, we provide [Drilling Rig Shaker Screens] that power HDD operations with unmatched [Solids Control]. Manufactured in China to [API Q1] standards, our screens are the perfect fit for HDD contractors like Vermeer, Ditch Witch, and America Augers. Let’s dive into why TOP SHAKER SCREEN is the top choice for your next HDD project.

How TOP SHAKER SCREEN Enhances Solids Control in Oil & Gas Drilling

In the fast-paced world of [Oil & Gas Drilling], efficient [Solids Control] is the backbone of successful operations. At TOP SHAKER SCREEN, a leading China-based manufacturer, we specialize in producing [Drilling Rig Shaker Screens] that meet the rigorous [API Q1] standard. Whether you’re a procurement manager at a [Mud Company] like Scomi Oiltools or an oilfield service provider like Baker Hughes, our products are designed to optimize your drilling process, reduce downtime, and boost profitability.

Petroleum Vibrating Screen: Technology for Oil Rigs

Unlock the benefits of petroleum vibrating screens for oil rigs. Enhance fluid management with cutting-edge technology!

Drilling Screen Mesh: Precision in Oil Extraction

Discover how drilling screen mesh ensures precision in oil extraction with top filtration. Improve your drilling efficiency now!

Oilfield Shaker Screen: Boosting Drilling Performance

Learn how oilfield shaker screens enhance drilling performance with efficient solids removal. Find the best options for your rig!

Vibrating Screen Mesh: Key to Solids Control in Petroleum

Explore the importance of vibrating screen mesh in petroleum drilling. Enhance solids control with top-quality mesh designs!

Shale Shaker Screen: Essential for Oil Drilling Efficiency

Discover how shale shaker screens boost oil drilling efficiency with durable designs and API standards. Learn their role in solids control today!

Solids Control Screen: Optimizing Drilling Fluid Systems

Optimize drilling fluid systems with solids control screens. Achieve efficient filtration and cost savings in oilfields!

Oil and Gas Drilling Equipment: Power of Shaker Screens

See how shaker screens power oil and gas drilling equipment. Enhance solids control and performance with top solutions!

Composite Shaker Screen: Next-Level Drilling Solutions

Discover composite shaker screens: next-level drilling solutions with lightweight, durable designs. Upgrade your rig today!

Stainless Steel Shaker Screen: Longevity in Oilfields

Learn why stainless steel shaker screens offer longevity in oilfields. Durable, efficient filtration for your rigs!

API Shaker Screen: Industry-Standard Filtration

Explore API shaker screens: industry-standard filtration for drilling. Ensure compliance and efficiency with top designs!

Petroleum Vibrating Screen: Technology for Modern Rigs

Unlock petroleum vibrating screen technology for modern rigs. Enhance solids control and efficiency in drilling!

Drilling Screen Mesh: Core Component of Oil Extraction

Discover drilling screen mesh: a key to oil extraction with precise filtration. Boost productivity with durable solutions!

Oilfield Shaker Screen: Maximizing Drilling Efficiency

Learn how oilfield shaker screens maximize drilling efficiency with top filtration. Optimize your rig performance now!

Vibrating Screen Mesh: Precision Filtration for Petroleum

Explore vibrating screen mesh for petroleum drilling. Achieve precision filtration and solids control with durable designs!

Shale Shaker Screen: Enhancing Oil Drilling Operations

Discover how shale shaker screens enhance oil drilling with efficient solids control. Learn about API standards and benefits today!

Replacement Shale Shaker Screens: Ensuring Uninterrupted Drilling Operations

Replacement shale shaker screens are essential for maintaining optimal performance in your drilling operations. Over time,

screens may wear out due to exposure to harsh drilling conditions. It’s important to replace them promptly to avoid interruptions

and maintain efficient solids separation. Choose replacement screens that are compatible with your existing shaker

and provide the necessary filtration for your drilling needs.

Shale Shaker Screen Materials: The Key to Durability and Performance

The material of the shale shaker screen plays a significant role in its durability and performance.

Common materials include stainless steel, polyurethane, and composite materials, each offering specific advantages depending

on the operating conditions. Choosing the right material can enhance the lifespan of the screen and improve its filtration capacity.

Derrick Shale Shaker Screens: A Reliable Solution for Solids Control

Derrick shale shaker screens are another popular choice in the drilling industry, known for their robust

construction and efficiency in solids control. These screens are used extensively in the oil and gas sector,

offering long-lasting performance and optimal separation. Derrick screens come in a variety of sizes and mesh options,

allowing for customized solutions for your specific needs.

Brandt Shale Shaker Screens: Industry-Leading Performance

Brandt shale shaker screens are renowned for their durability and exceptional performance.

Used by drilling contractors worldwide, these screens offer reliable separation of solids from drilling fluids.

Available in various mesh sizes and configurations, Brandt screens are perfect for a range of applications.

They are especially popular for their long service life and ability to withstand harsh operating conditions.

The Best Shale Shaker Screen for Your Drilling Operations

Finding the best shale shaker screen depends on factors like the type of well, fluid conditions, and the types of

particles to be separated. Composite frame screens, steel frame screens, and other advanced materials can offer

superior performance in various conditions. Selecting the right screen ensures the efficiency of your drilling process

and helps maintain wellbore stability.

API Shale Shaker Screen Sizes: Compliance and Performance

API shale shaker screen sizes are standardized according to the API RP 13C specification.

These screens are commonly used in the oil and gas industry for their reliability and consistent performance.

Understanding the API shale shaker screen sizes is crucial for ensuring compliance and efficiency in your drilling operations.

With a wide range of API-compliant screens available, you can choose the right screen for your specific needs.

Shale Shaker Screen Suppliers: Finding the Right Partner

Choosing a reliable shale shaker screen supplier is critical to maintaining high-performance drilling operations.

It’s essential to find suppliers who offer a wide range of screen types, sizes, and materials.

Look for suppliers with a reputation for quality and durability,

and who understand the specific requirements of your industry. Whether you’re located in Singapore or

any other part of the world, selecting the right supplier can help streamline your operations.

Shale Shaker Screen Mesh Sizes: How to Choose the Best One for Your Drilling Needs

The mesh size of a shale shaker screen determines the type of particles it can filter.

A finer mesh size is ideal for separating smaller particles, while a coarser mesh works for larger ones.

Understanding shale shaker screen mesh sizes is essential for optimizing the separation process.

A mesh size table can help you select the appropriate screen for your specific needs, ensuring maximum efficiency and effectiveness.

Shale Shaker Screen Sizes: A Comprehensive Guide

Choosing the right shale shaker screen size is crucial to achieving optimal performance in your drilling operations.

thale shaker screens come in various sizes, including API and custom sizes.

The size you select should be based on factors like the type of well, the nature of the drilling fluid,

and the type of solids to be filtered. A mismatch between screen size and application can lead to inefficiency,

so understanding shale shaker screen sizes is essential.

Shale Shaker Screen Sizes: A Comprehensive Guide

Choosing the right shale shaker screen size is crucial to achieving optimal performance in your drilling operations. thale shaker screens come in various sizes, including API and custom sizes. The size you select should be based on factors like the type of well, the nature of the drilling fluid, and the type of solids to be filtered. A mismatch between screen size and application can lead to inefficiency, so understanding shale shaker screen sizes is essential.

Understanding Shale Shaker Screens: The Essential Tool for Drilling Operations

Shale shaker screens are integral components in the drilling process. These screens help separate solids from the drilling fluids, ensuring efficient and effective operations. There are various types of shale shaker screens available, including composite frame, steel frame, and hook-strip screens, each designed to suit different drilling needs. The mesh sizes vary,

Vibrating screen, classification of shale vibrating screen

Shaker screens patterns

To distinguish screen patterns, there are many references or methods. Firstly, we can judge it according to appearance. Such as flat panels and corrugated panels. Sometimes, we’ll call it flat-panel “PWP”(Trademark of Derrick® corporation), and we’ll call panel with corrugation wave “PMD” (Trademark of Derrick® corporation). It’s an abbreviation of “pyramid”.

Enhanced Features of SS316 Shale Shaker Screen for Oil & Gas Drilling Applications

SS316 Shale Shaker Screens, made from premium stainless steel mesh, are crucial components for the oil and gas

drilling industry. These screens are designed to separate and filter drilling fluids efficiently, ensuring high performance and durability.

Here’s a closer look at the key features of SS316 Shale Shaker Screens that make them an ideal choice for demanding drilling environments.

Top Shaker Screen: The Ultimate Solution for Oil Drilling shaker Screen

Top Shaker Screen: The Ultimate Solution for Efficient Oil Drilling Operations

Shaker screen is a crucial component in the process of oil drilling,

as its quality directly affects the efficiency and effectiveness of the

drilling process. Our top shaker screen products are manufactured

with advanced technology and high-quality materials, and they offer the following advantages:

Interpret API RP 13C in the Form of Question & Ans

Once we identify the cut point and conductance complying with API RP 13C, a permanent tag or label should be attached on the visible and legible position of the screen. Both cut point expressed as an API number and conductance shown in kD/mm are required on the screen label.

Internationally, API RP 13C is ISO 13501.The new procedure is a revision of the previous API RP 13E.

Comprehensive Guide to Oil Drilling Shale Shaker Screens: Types, Mesh Sizes, and Brands

The oil drilling shale shaker screen is a key component in oil drilling operations. It is a vibrating screen designed to separate solids from drilling fluids, ensuring the efficient recovery of drilling mud. Typically, these screens are made of a metal frame with mesh material, and they play an essential role in maintaining the proper functioning of the drilling system.

Top Shaker Screen: The Ultimate Solution for Oil Drilling shaker Screen

Shaker screen is a crucial component in the process of oil drilling, as its quality directly

affects the efficiency and effectiveness of the drilling process. Our top shaker screen products

are manufactured with advanced technology and high-quality materials, and they offer the following advantages:

Understanding Oil Drilling Shale Shaker Screens: Types, Mesh Sizes, and Leading Brands

In oil drilling operations, shale shaker screens are essential for separating solids from drilling fluids,

ensuring efficient drilling processes. These screens vary in type, mesh size, and construction, each suited to specific operational needs.

Understanding Shale Shaker Screen Types: Hookstrip Flat Screens vs. Shaker Screens

Introduction: In oil drilling operations, selecting the appropriate shale shaker screen is crucial for

efficient solids control and optimal drilling performance. Two common types are Hookstrip

Flat Screens and Shaker Screens, each with distinct construction and benefits.

Common Issues in Oil Drilling Shale Shaker Operations and Effective Solutions

Efficient operation of shale shakers is crucial for effective solids control in oil drilling. Addressing common issues promptly can enhance performance and extend equipment lifespan.

A Comprehensive Guide to Purchasing High-Quality Shale Shaker Screens for Oil Drilling Operations

Selecting the right shale shaker screen is crucial for optimizing solid control efficiency in oil drilling operations. High-quality shaker screens ensure effective separation of solids from drilling fluids, enhancing operational efficiency and reducing costs.

Enhancing Drilling Efficiency with Premium Shale Shaker Screens

In oil and gas drilling operations, maintaining the quality of drilling fluids is essential for operational efficiency and cost-effectiveness. Shale shaker screens are pivotal in this process, effectively separating solids from drilling fluids to ensure optimal performance.

Understanding Shaker Screens and Shale Shakers in Oil and Gas Drilling Operations

In oil and gas drilling operations, maintaining the integrity of drilling fluids is crucial for efficient and cost-effective drilling. Shaker screens and shale shakers play a pivotal role in this process by effectively separating solids from drilling fluids.

High-Performance Replacement Shaker Screens for KEMTRON KTL 48 Series Shale Shakers

The TP-KTL-48 shaker screens are engineered as premium replacements for KEMTRON KTL 48 series shale shakers, including models such as KTL-448 AG four-panel shaker, KTL-48 STD three-panel shaker, KTL-48D three-panel shaker, and KTL-48 SS three-panel shaker. These screens are also compatible with KEMTRON 48 series desanders and desilters. Designed to maximize solids removal and discharge dryness, they are available in mesh types ranging from API 20 to API 230, catering to various drilling conditions.

High-Quality Replacement Shaker Screens for SWACO MONGOOSE PRO and MEERKAT PT Shale Shakers

The TP-MON/1 shaker screens are engineered to serve as premium replacement screens for SWACO MONGOOSE PRO and MEERKAT PT shale shakers. These screens are available in both steel and composite frame types, offering flexibility to meet diverse operational requirements. Designed to fit seamlessly into the shaker baskets—four pre-tensioned screens per basket for MONGOOSE units and three per basket for MEERKAT units—these screens ensure optimal performance and efficiency.

Frequently Asked Questions About Oil Drilling Shale Shakers and Screens

Oil drilling shale shakers are critical equipment in the oil and gas industry, used to separate solids from liquids during the drilling process. These vibrating screens ensure that the drilling fluids remain clean and free of debris, helping to maintain the efficiency of drilling operations. Below, we answer some of the most frequently asked questions about oil drilling shale shakers and their screens.

Shaker screens are an essential part of the drilling process for the oil and gas industry.

Shaker screens are an essential part of the drilling process for the oil and gas industry. They are used in shale shaker screens, which are large vibrating screens used to remove solid particles and impurities from the drilling mud. Top shaker screens are an important component of shale shaker systems and are critical to the efficiency of the drilling process. Here are some frequently asked questions about shaker screens and their use:

1.

What is a shaker screen? A shaker screen is a mesh screen designed to filter and separate solids from drilling fluid. It is typically made of stainless steel wire mesh and can come in a variety of sizes and shapes depending on the application.

2.

3.

How does a shaker screen work? During the drilling process, drilling mud flows into the shale shaker screen, which vibrates rapidly, causing the solids to separate from the fluid. The fluid then flows through the screen, while the solids are retained on the surface.

4.

5.

What are the different types of shaker screens? There are many different types of shaker screens available, including flat screens, pyramid screens, and hook strip screens. Each type has its own unique features and benefits.

6.

7.

How do I choose the right shaker screen for my application? The right shaker screen will depend on a variety of factors, including the size and shape of the solids you are trying to separate, the size of the shaker screen, and the type of drilling fluid you are using. Consult with a shaker screen expert to determine the best option for your specific needs.

8.

9.

How often should I replace my shaker screen? The frequency of shaker screen replacement will depend on the volume and type of drilling being performed. In general, shaker screens should be inspected regularly and replaced as needed to ensure maximum efficiency.

10.

If you are in need of shaker screens, be sure to choose a reputable supplier with a wide range of products and a history of delivering quality and reliable solutions. With the right shaker screen, you can ensure that your drilling process is efficient and effective, helping to maximize productivity and minimize downtime.

Common Issues with Oil Drilling Shale Shaker and Effective Solutions for Maintaining Performance

Oil drilling operations require efficient equipment to handle large volumes of mud and debris.

The shale shaker is one of the most critical pieces of machinery used in these operations.

It separates unwanted particles from drilling fluids, but like all equipment, it can experience common issues.

Understanding how to maintain and troubleshoot your shale shaker screen can help improve performance,

minimize downtime, and ensure the success of your drilling project. Here are some of the most common problems

faced by users of oil drilling shale shakers, along with actionable solutions to resolve them.

The Three Main Characteristics of Vibration in Drilling

The Three Main Characteristics of Vibration in Drilling

Key Parameters for Measuring Vibration in Drilling

Understanding Amplitude, Frequency, and Duration in Vibration Analysis To accurately measure and assess vibration during drilling, three key parameters are used: Amplitude: The

Understanding the Causes of Vibration in Drilling Operations

Identifying Key Factors Behind Vibration and How to Address Them Vibration is a common challenge during drilling operations, and understanding its causes is

How Oil Companies Determine the Best Locations for Drilling

Techniques and Technologies Used to Identify Optimal Drilling Sites Oil companies rely on advanced techniques and technologies to determine the best locations for

Effective Methods to Reduce Vibration During Drilling

Tips and Solutions to Minimize Drilling Vibration and Enhance Efficiency Drilling vibrations can lead to inefficient operations, causing excessive wear on equipment and

How to Choose the Right Petroleum Drill Vibration Sieve Network for Optimal Performance

petroleum drill vibration sieve, shale shaker screens, particle size separation, drilling equipment, sieve selection

Meta Description: Learn how to choose the best petroleum drill vibration sieve network. Understand key factors like particle size,

material type, and throughput for efficient drilling operations.

High-Performance Shale Shaker Screens for Oil Drilling: Enhance Efficiency and Durability

In the demanding world of oil drilling, the efficiency of your equipment can significantly impact the success of operations. Among these crucial tools, shale shaker screens play an indispensable role in separating drilled solids from the drilling fluid. Choosing high-performance shale shaker screens is essential for maintaining smooth operations, reducing downtime, and improving overall efficiency. In this article, we explore the importance of quality shale shaker screens and how they contribute to enhanced drilling performance.

Shale Shaker Screen Mesh Sizes Table: A Quick Reference

API Number: A standardized size rating by the American Petroleum Institute.

Mesh Count: The number of openings per inch in the screen.

Micron Size: The size of particles the screen can filter.

Sample Table

API Size Mesh Count Micron Size Application

API 20 20 780 Coarse particles

API 80 80 180 Medium solids

API 200 200 74 Fine filtration

Conclusion

A mesh sizes table simplifies decision-making, helping you select screens tailored to your drilling needs.

How to Choose the Best Screen Shale Shaker for Your Needs

Overview of shale shaker screens.

1.Factors to Consider:

2.Mesh size requirements.

3.Compatibility with shaker models.

4.Operating environment (temperature, pressure).

Tips for Maintenance: Cleaning and storing the screens.

Conclusion: Emphasize durability and compatibility when selecting screens.

How to Find Reliable Shale Shaker Screen Suppliers

Introduction: Importance of trusted suppliers.

Characteristics of Reliable Suppliers:

API certification.

High-quality materials.

Excellent customer service.

Benefits of Partnering with Trusted Suppliers: Cost savings, consistent quality.

Conclusion: Recommend researching supplier reviews.

Understanding Shale Shaker Screen Sizes: A Complete Guide

Introduction: Importance of screen sizes in drilling operations.

Standard Sizes: Overview of API standards for screen sizes.

Application of Different Sizes: Match sizes to drilling fluid conditions.

Choosing the Right Size: Factors to consider, like particle size distribution.

Conclusion: Proper screen size selection enhances efficiency.

Welcome to Top Shaker Screen, a leading manufacturer specializing in

high-performance shale shaker screens and advanced drilling solutions.

Located in the heart of Anping County, Hebei Province—China’s renowned

“Hometown of Wire Mesh”—our company combines decades of expertise

with cutting-edge technology to deliver unparalleled products to the oil and gas drilling industry.

Shale Shaker Screens Sizes: What You Need to Know

Understanding shale shaker screens sizes is vital for optimizing your drilling operations.This article covers essential information about sizes and their practical applications. Why

Shale Shaker Screen Mesh Sizes Table: All You Need to Know

Introduction: Purpose of mesh size tables.

Explanation of Terms: API number, mesh count, and micron size.

Sample Table: Include examples of API sizes and their corresponding applications.

Tips for Selection: Optimize performance based on mesh size table reference.

Conclusion: How the table aids in making informed decisions.

What Are Shale Shaker Screens and Their Key Functions?

Introduction: Define shale shaker screens and their role in drilling operations.

Main Functions:

Removing solid particles from drilling fluid.

Enhancing drilling efficiency and reducing downtime.

Types of Screens: Mesh, hook-strip, and composite frame.

Conclusion: Highlight the importance of using high-quality shale shaker screens for efficient drilling.

Innovative Shaker Screens, Unmatched Performance

Consider the particle size distribution in your drilling fluid.

Match the screen size with the type of shale shaker in use.

Always consult the API RP 13C guidelines.

Conclusion

Selecting the correct shale shaker screen size enhances drilling efficiency and reduces downtime. For reliable options, always choose API-compliant screens.

Understanding Shale Shaker Screen Mesh Sizes

Shale shaker screen mesh sizes determine the efficiency of particle separation. In this article, we delve into the importance of mesh sizes and

A Comparison of Shale Shaker Screen Mesh Sizes

Mesh size is a critical aspect of shaker screen performance.

Common Mesh Sizes

API standards offer mesh sizes for various drilling conditions.

Performance Impact

Fine mesh enhances filtration but reduces flow rate.

Coarse mesh improves flow but may miss smaller particles.

Finding Reliable Shale Shaker Screen Suppliers

API Certification: Ensure the supplier complies with API standards for screen sizes.

Material Quality: High-quality materials guarantee durability and performance.

Customer Support: Look for suppliers offering technical guidance and after-sales services.

Benefits of Partnering with Trusted Suppliers

Consistent Quality: Reduces equipment wear and operational downtime.

Cost Efficiency: Saves money in the long run through durable products.

Conclusion

Researching supplier reviews and choosing API-compliant products is key to finding the best shale shaker screen suppliers.

Top 5 Benefits of High-Quality Shale Shaker Screens

Introduction: Why investing in quality screens matters.

1.Improved fluid recovery.

2.Longevity under extreme conditions.

3.Cost-efficiency in operations.

4.Enhanced drilling accuracy.

5.Easy maintenance

Shale Shaker Screen Supplier Singapore: Local Expertise for Global Needs

Faster Delivery: Proximity ensures timely delivery.

Regional Knowledge: Local suppliers understand the specific challenges of Asia-Pacific drilling conditions.

Competitive Pricing: Reduced logistics costs make local suppliers cost-effective.

What to Look for in a Singapore Supplier

Top 5 Benefits of High-Quality Shale Shaker Screens

Conclusion: Recommend choosing screens with API certification.

Using premium shale shaker screens can significantly enhance drilling operations.

Benefits

1.Fluid Recovery: Reduces fluid waste, saving costs.

2.Durability: Performs reliably under extreme conditions.

3.Cost Efficiency: Prolonged lifespan reduces replacement costs.

4.Drilling Accuracy: Maintains optimal fluid flow for precision drilling.

5.Ease of Maintenance: Simplifies cleaning and replacement.

Choose API-certified screens for unmatched reliability and performance.

API Shale Shaker Screen Sizes: A Standardized Guide

Introduction: Importance of API standards.

API Size Explained: Overview of API RP 13C standards.

How It Impacts Performance: Consistency, reliability, and international compatibility.

Guide to Selecting API-Compliant Screens: Practical tips for buyers.

Conclusion: API sizes ensure the highest performance and reliability.

Comprehensive Guide to Shale Shaker Screen Sizes

Shale shaker screen sizes play a crucial role in the drilling industry by determining filtration efficiency

and performance. In this guide, we explore the significance of screen sizes and how they impact operations.

What Are Shale Shaker Screen Sizes?

Shale shaker screen sizes refer to the mesh dimensions used to filter solid particles from drilling fluids.

These sizes are defined using API standards, ensuring consistency across applications.

Shale Shaker Screen Supplier Singapore: Why Choose Local Experts?

Introduction: Overview of Singapore’s oil and gas market.

Why Local Suppliers Are Beneficial:

Faster delivery times.

Better understanding of regional needs.

Competitive pricing.

Top Features to Look For: API certification, robust product lineup.

Conclusion: Emphasize the value of working with local experts.

ZOYA CREATIVE BLOG

HENDRIK MORELLA

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.