The HDD Solids Control Challenge

HDD demands precise mud management to maintain borehole stability and protect equipment. Without effective [Solids Control], debris can slow progress and damage costly [Drilling Equipment]. TOP SHAKER SCREEN’s [Drilling Rig Shaker Screens] tackle these issues head-on, offering durability and efficiency tailored to [Horizontal Directional Drilling] needs.

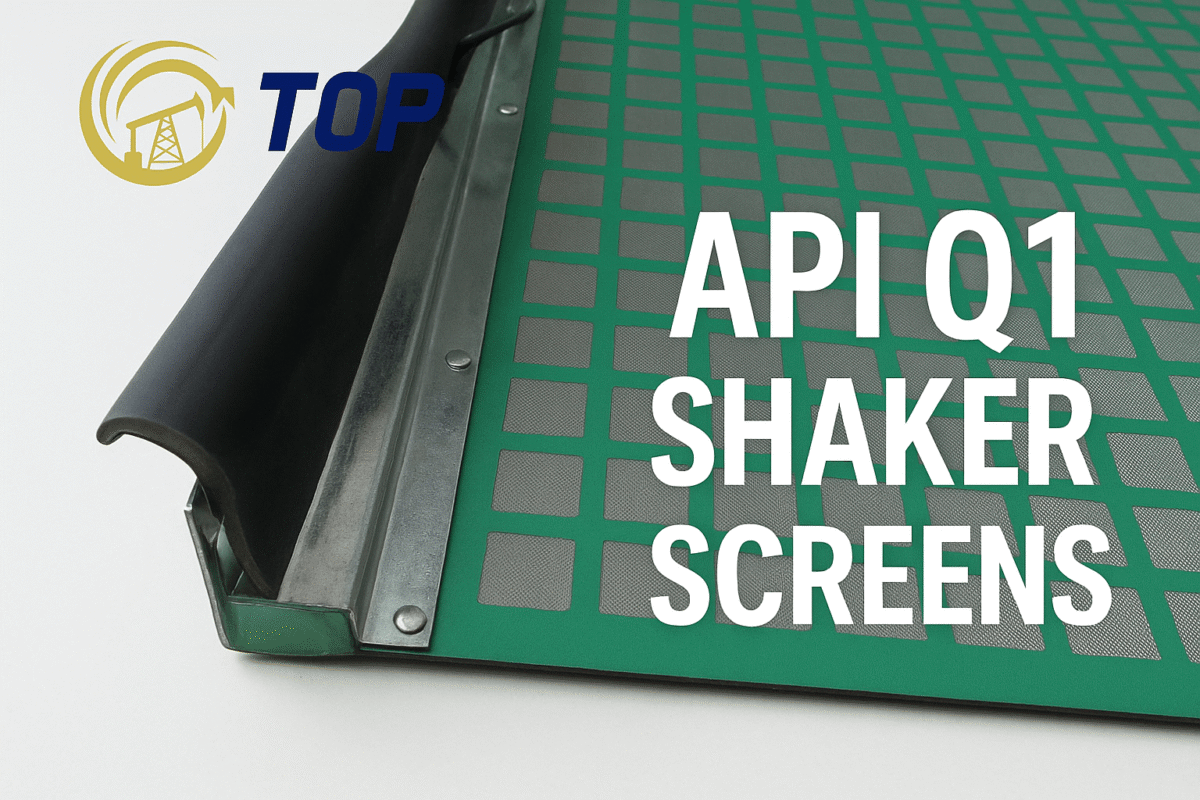

What Sets TOP SHAKER SCREEN Apart

- API Q1 Quality: Certified for global standards, ensuring reliability in tough HDD conditions.

- High Filtration Capacity: Our screens remove solids fast, keeping your mud clean and your project on track.

- Compatibility: Seamlessly integrates with HDD rigs from Vermeer to Prime Drilling, enhancing your [Oilfield Supplies] lineup.

Contractors in Australia and the Middle East trust TOP SHAKER SCREEN to deliver consistent results, no matter the soil type or project scale.

A Case Study in HDD Success

Consider an Australian HDD project: a contractor using Ditch Witch rigs faced delays due to inefficient screens. After switching to TOP SHAKER SCREEN, they improved [Solids Control] by 25%, completing the job ahead of schedule. This is the kind of impact our [Drilling Equipment] brings to [Horizontal Directional Drilling]—efficiency you can count on.

Take Your HDD Project Further

Looking to upgrade your [Oilfield Supplies]? Visit https://topshaleshakerscreen.com to see how TOP SHAKER SCREEN can transform your [Horizontal Directional Drilling] operations. Contact us for a custom solution and keep your projects running smoothly.