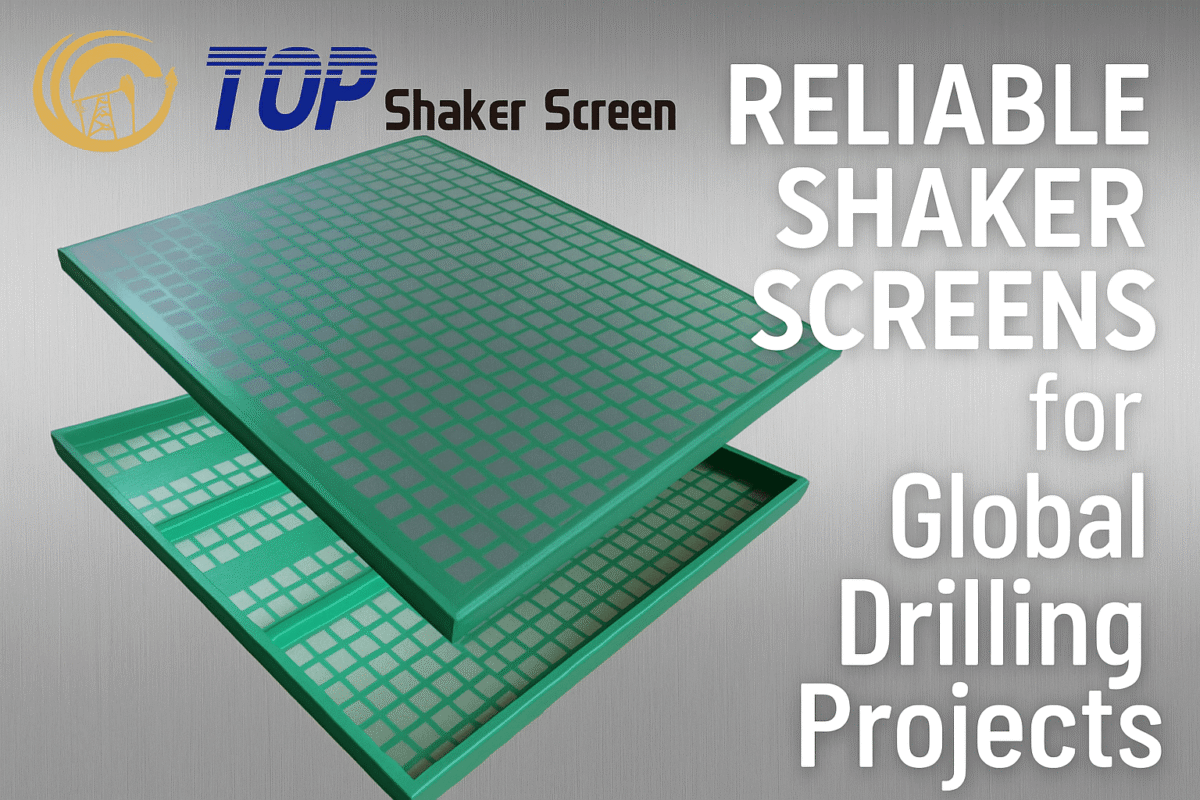

1) Optimized Layer Density for Superior Screening Performance

The SS316 Shale Shaker Screen utilizes multiple layers with different mesh densities.

By strategically arranging these layers, the screening effect is enhanced for optimal

separation of solid particles from drilling fluids. The combination of various mesh counts

and appropriate opening sizes for the backing plate ensures the largest effective screen

area while maintaining the necessary strength. This leads to better filtration and longer-lasting performance.

2) Durable Bottom Layer for Increased Strength and Longevity

The bottom layer of the SS316 Shale Shaker Screen is designed with low mesh counts and

coarse wire. This layer is tightly bonded to the backing, forming a solid block that enhances

the overall strength of the screen. This design not only improves the screen’s structural integrity

but also extends its lifespan, reducing the frequency of replacements and lowering operational costs.

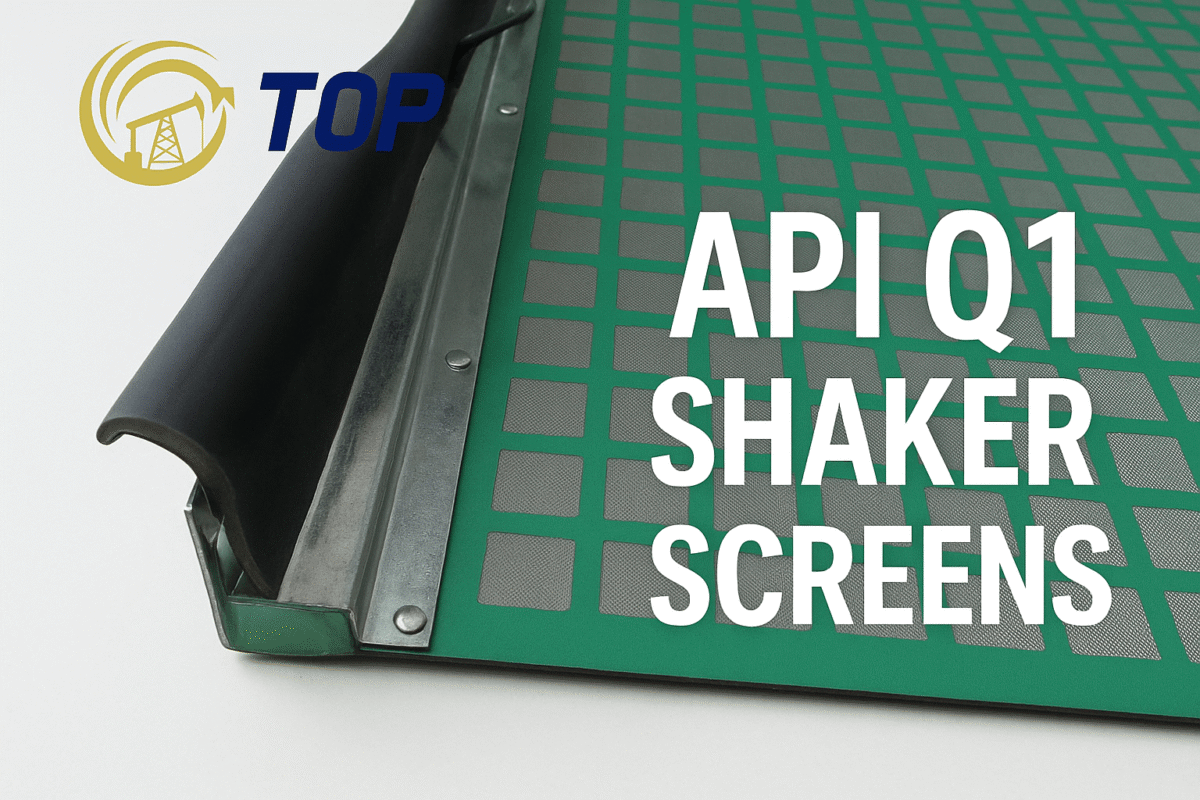

3) Grid-Partitioned Mesh for Enhanced Damage Control

The mesh is divided into multiple small independent units by the grid structure of the backing plate.

This innovative design prevents tears from spreading across the entire screen, thereby minimizing potential

damage and downtime. Additionally, rubber stoppers are available as accessories to facilitate easy repairs.

By using these stoppers, operators can quickly restore the screen’s functionality, reducing costly stop time

and maintaining drilling efficiency.

Conclusion:

SS316 Shale Shaker Screens are built to withstand the rigors of oil and gas drilling, offering unmatched durability

and performance. With advanced features like optimized mesh density, durable layers, and damage control grids,

these screens ensure the effective and reliable filtration of drilling fluids. Investing in high-quality SS316 Shale Shaker Screens

will improve operational efficiency, lower maintenance costs, and extend the life of drilling equipment.