Shaker screens are an essential part of the drilling process for the oil and gas industry. They are used in shale shaker screens, which are large vibrating screens used to remove solid particles and impurities from the drilling mud. Top shaker screens are an important component of shale shaker systems and are critical to the efficiency of the drilling process. Here are some frequently asked questions about shaker screens and their use:

1.

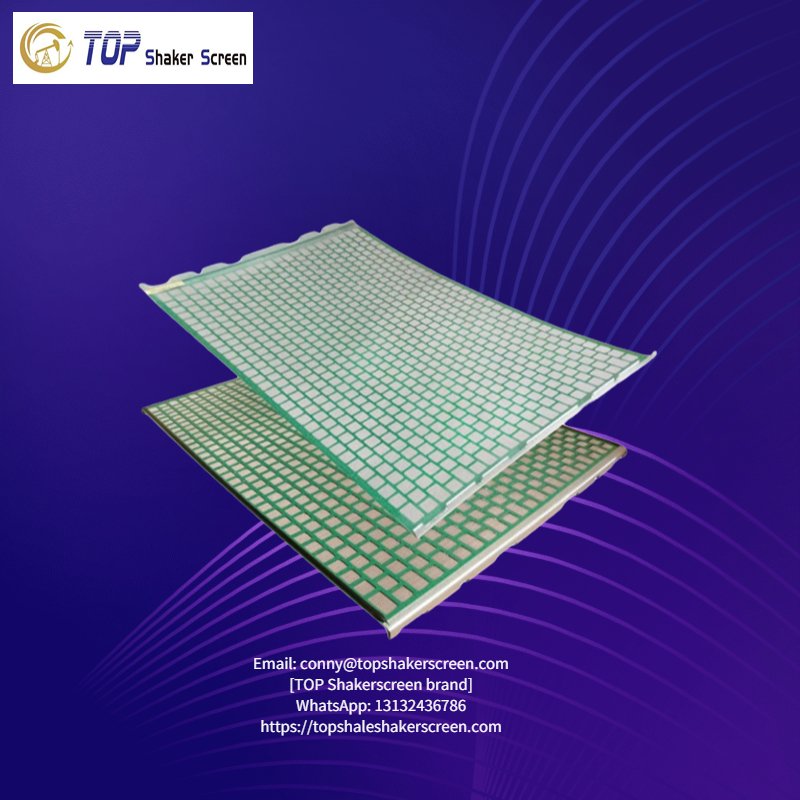

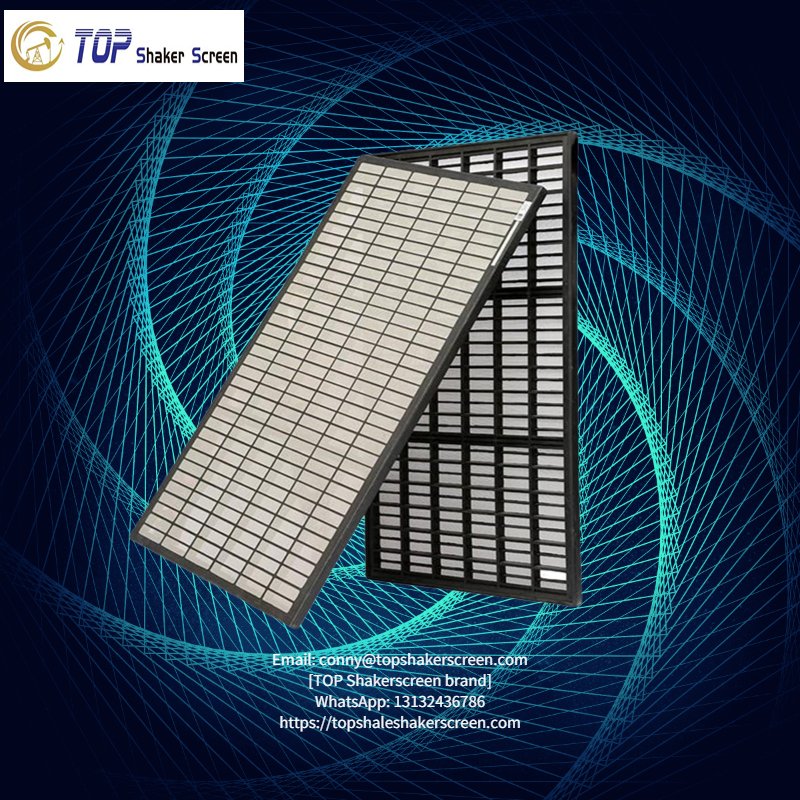

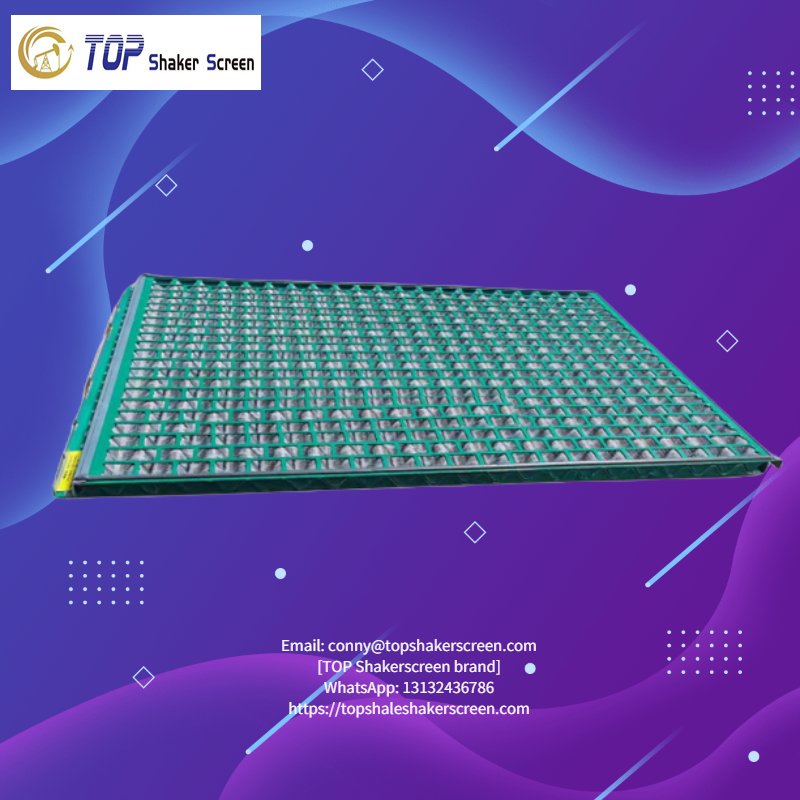

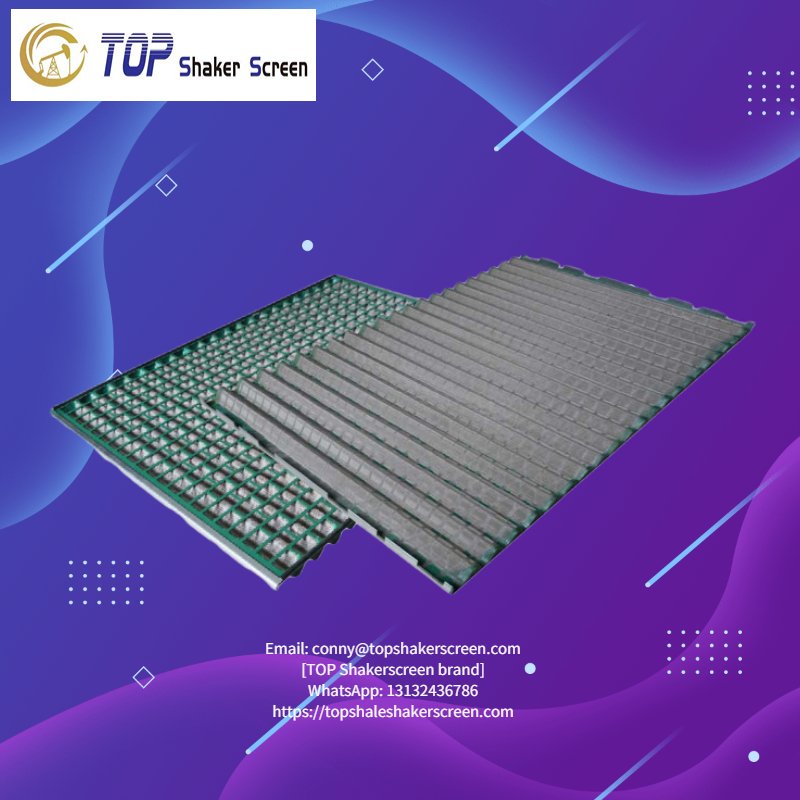

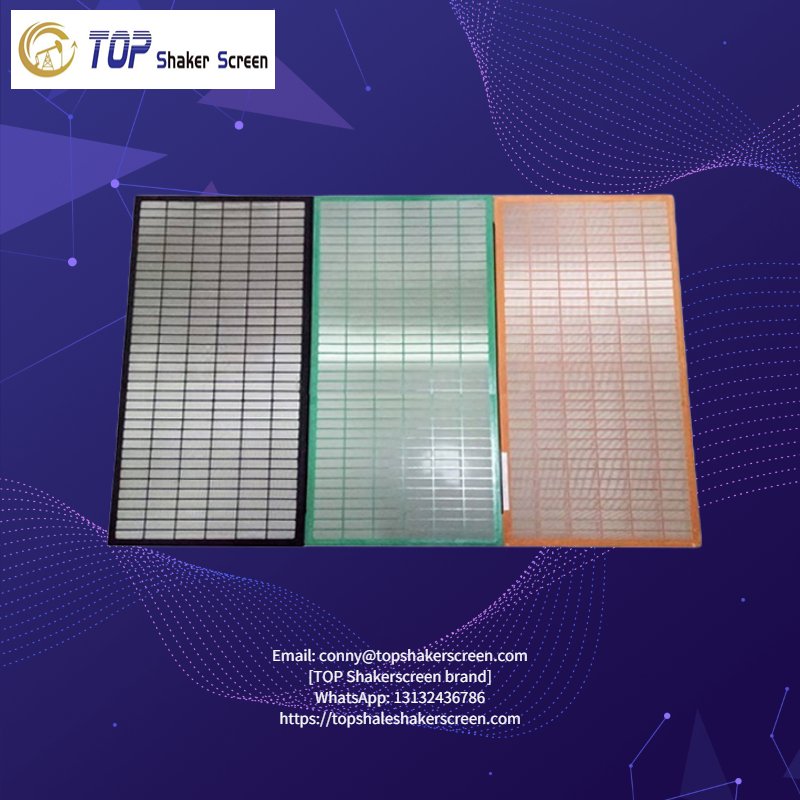

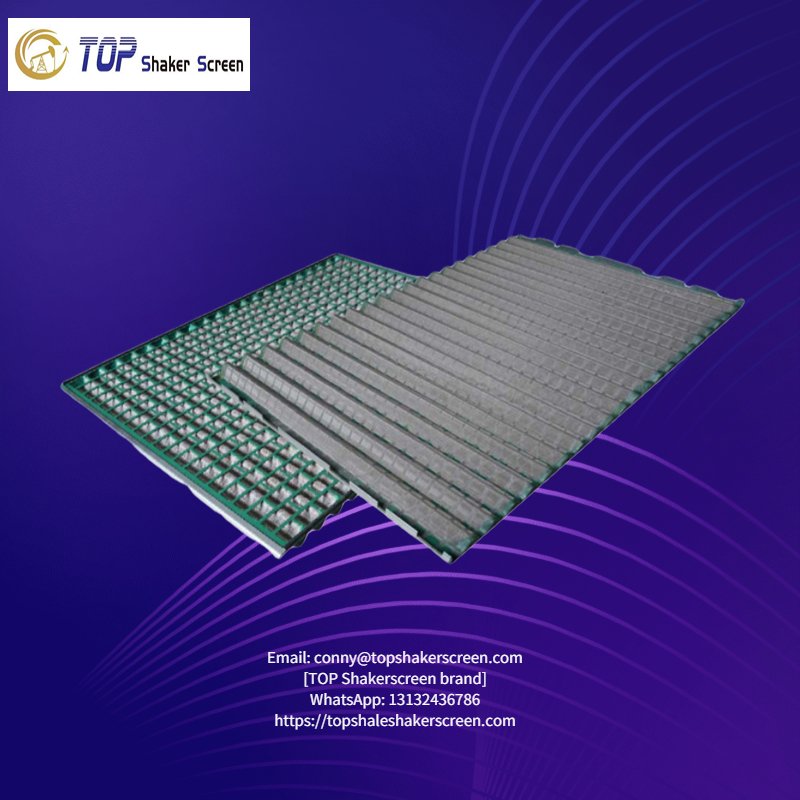

What is a shaker screen? A shaker screen is a mesh screen designed to filter and separate solids from drilling fluid. It is typically made of stainless steel wire mesh and can come in a variety of sizes and shapes depending on the application.

2.

3.

How does a shaker screen work? During the drilling process, drilling mud flows into the shale shaker screen, which vibrates rapidly, causing the solids to separate from the fluid. The fluid then flows through the screen, while the solids are retained on the surface.

4.

5.

What are the different types of shaker screens? There are many different types of shaker screens available, including flat screens, pyramid screens, and hook strip screens. Each type has its own unique features and benefits.

6.

7.

How do I choose the right shaker screen for my application? The right shaker screen will depend on a variety of factors, including the size and shape of the solids you are trying to separate, the size of the shaker screen, and the type of drilling fluid you are using. Consult with a shaker screen expert to determine the best option for your specific needs.

8.

9.

How often should I replace my shaker screen? The frequency of shaker screen replacement will depend on the volume and type of drilling being performed. In general, shaker screens should be inspected regularly and replaced as needed to ensure maximum efficiency.

10.

If you are in need of shaker screens, be sure to choose a reputable supplier with a wide range of products and a history of delivering quality and reliable solutions. With the right shaker screen, you can ensure that your drilling process is efficient and effective, helping to maximize productivity and minimize downtime.